After the block modifications, it's time to install the piston oil jets. Do this before installing the crank, otherwise you get to take all ten bolts out again (and replace them if you torqued them to yield). I checked that all the check valves were operating fluidly and that none of the jets were clogged. Then the bolts get locktite (important!) and get torqued to approximately 7 ft-lbs.

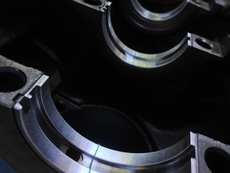

Then the crank got put in. This was just polished and mic'd at the machine shop, but I measured radial clearances anyway. The mains were about .38mm, which is a tad toward the worn side of the standard-sized spec. I believe this crank has somewhere over 315k miles on it— not too bad.

This is where I hit my first snag.

The machine shop removed the crank timing wheel (028 105 189 B) for some reason. As I can't see it interfering with anything, I had planned to ask them to leave it on but forgot. I've read different accounts on how to handle this.The Bentley says the three torx screws should be replaced, but nothing about the wheel. Others say the wheel gets deformed when installed and can't be reused. Still others have simply bent damaged wheels back into place and reused both the wheel and bolts. As VW wanted $4 for each screw and couldn't get them for a week I opted to reuse them with plenty of loctite. I think the contention is that the shoulder of the screws eats into the wheel on assembly, and retorquing holds the posibility that they won't bite properly. I hope I don't regret the decision.

After cleaning everything, I applied assembly lube and torqued everything down. It spins freely after being torqued, so I should be in good shape there.

Pistons

I bought brand new Nüral .5mm oversized pistons for this build. The last motor I build I simply honed the cylinders and used a balanced set of used pistons and rods. So I didn't think about balancing until I was ready to get out my ring compressor. After my little guy gets up from his nap I'll be headed to pick up a scale to see how close they are. If they're out by more than a gram or so I suppose I'll be figuring out where I can remove material from. I doubt this engine will see 4000 RPM more than a few times in its life, but I want to do it right.

I bought brand new Nüral .5mm oversized pistons for this build. The last motor I build I simply honed the cylinders and used a balanced set of used pistons and rods. So I didn't think about balancing until I was ready to get out my ring compressor. After my little guy gets up from his nap I'll be headed to pick up a scale to see how close they are. If they're out by more than a gram or so I suppose I'll be figuring out where I can remove material from. I doubt this engine will see 4000 RPM more than a few times in its life, but I want to do it right.

So I got a scale

As of right now, the piston/rod assemblies weigh as such:

Total

| Cyl | Piston | Pin | Rod | Total |

|---|---|---|---|---|

| 1 | 579.0 | 205.9 | 731.2 | 1516.1 |

| 2 | 579.3 | 203.6 | 730.8 | 1513.7 |

| 3 | 576.7 | 204.3 | 731.8 | 1512.8 |

| 4 | 576.3 | 204.2 | 729.2 | 1509.7 |

| Min | 576.3 | 203.6 | 729.2 | 1509.7 |

| Max | 579.3 | 205.9 | 731.8 | 1516.1 |

| Deviation | 3.0 | 2.3 | 2.6 | 6.4 |

However, if I balance all pistons by themselves, then swap the heaviest pin with the lightest rod and visa-versa, we get a lot closer.

- Pin 4 goes to piston 1 and Pin 1 goes to piston 4

- Pin 3 goes to piston 2 and pin 2 goes to piston 3

| Cyl | Piston | Pin | Rod | Total |

|---|---|---|---|---|

| 1 | 576.3 | 204.2 | 731.2 | 1511.7 |

| 2 | 576.3 | 204.3 | 730.8 | 1511.4 |

| 3 | 576.3 | 203.6 | 731.8 | 1511.7 |

| 4 | 576.3 | 205.9 | 729.2 | 1511.5 |

| Min | 576.3 | 203.6 | 729.2 | 1511.4 |

| Max | 576.3 | 205.9 | 731.8 | 1511.7 |

| Deviation | 0.0 | 2.3 | 2.6 | 0.3 |

300 miligrams is definitely close enough for me. Now I just have to figure out how to remove around 3 grams from piston 1 and 2. I've read that the bottom of the piston pin boss is a safe area to remove from. Also, I do not have cooling gallies in these pistons, so no worries about breaching them. I'll try to read more, but tomorrow will probably be filing away at brand new imported pistons.

Or Maybe Not

Weighing 2&3 against 1&4 leaves me with a .7 grams difference between reciprocating masses.

(1513.7 + 1512.8) - (1516.1 + 1509.7) = 700 mg

I've read some caution about swapping piston pins around, even in brand new pistons, and been advised to think of deviations in terms of percentages. Right now, from the heaviest asssmbly to the lightest I'm 0.4% off. For a slow-reving diesel I'm not sure it's worth the risk of unbalancing individual pistons.

While I'm sure that someone will give me the downlow just after I torque the rod caps to yield, I think I'm going to install the pistons as they are. The Bentley says to offset all ring gaps by 120° and then get your crappy ring compressor out of the shed, clean everything well and then use plenty of oil. They fit like a dream.

Conclusion

So there we go, the oil jets are in (and loctite'd), the crank is in and spinning freely, and the pistons are in. As a testament to my level of confidence at this point, the rod cap bolts are not yet torqued to yield (Bentley calls for an additional 90° turn after 22 ft-lbs), but I don't yet have the oil pan anyway.

So there we go, the oil jets are in (and loctite'd), the crank is in and spinning freely, and the pistons are in. As a testament to my level of confidence at this point, the rod cap bolts are not yet torqued to yield (Bentley calls for an additional 90° turn after 22 ft-lbs), but I don't yet have the oil pan anyway. ![]()